Objectives:

The project purpose was to carry the previous ‘breadboard’ development of a High-Pressure Proportional Valve that started in 2008. Additionally develop all aspects of this design and then build an electronic pressure regulator sub-system and take it via comprehensive development and Engineering Model testing with a range of typically used spacecraft combustibles.

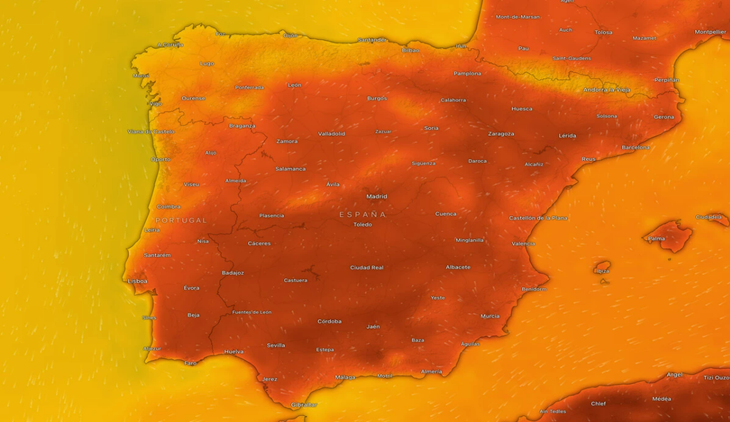

The electro pneumatic pressure regulator makes the whole system consistent with Xenon, Helium, Nitrogen, Hydrazine, and MON. Note the use of a specifically designed Heater unit in the schematic to eradicate Joule Thompson problems regarding Xenon phase change through whole at higher flow rates such as those required for Cold Gas Thrusters. The heater of air pressure controller is not needed for the other gases and propellants.

Challenges:

The key challenges of an electronic pressure control associated with meeting the demanding project objectives were:

- Coping with a pressure range from 0 to 310bara, a flow range of <3 to 600mg/s Xenon & Helium and accommodating 3 different propellants (Xenon, Nitrogen, and Helium) with a single proportionally regulating valve design.

- Overcoming Xenon Joule Thompson’s issues

- Developing hard material sealing technology

- Thermally compensating design

Benefits:

Benefits of an electronic pressure regulator is given as:

In-flight pressure variation and control throughout mission life. Programmable by telecommand.

Features:

Following are the key features of electronic pressure controllers that include:

- Consistent with all heritage spacecraft propellants and pressurant.

- Appropriate for flow control of liquids and gases.

- Regulation accuracy of <0.05 bar (mechanical regulation is typical>0.2 bar).

- Response to 90% of new level <1 second.

- No need for multiple regulators (as in the mechanical case).

- Low leak rate (<2 x 10-5 SCC/sec Helium internal).

- High Flow capacity > 600mg/s Xenon at EoL, >600mg/s Helium at EoL.

- Up to 310 bar MEOP.

- The pressure set point range is 0.5 to 22 bar.

- In-orbit data logging.

- The electric pressure valve system design for Electric Propulsion applications includes thermal conditioning of Xenon (or Nitrogen) to prevent Joule-Thompson problems and regulate outlet pressure & minimum temperature.

The electric pressure valve:

The Engineering Model EPR can be in the ‘as tested’ configuration. Gold-plated Xenon heater can be seen on the left. This flows pre-conditioned Xenon into the High-Pressure Proportional Valve (HPPV) instantly to its right and hence to the thruster interface at the bottom of the electro pneumatic regulator.

The electronic pressure regulator seen at the top is functioning as a high-pressure isolation valve as this has been proven at 310bara to perform to needs. The valve is low mass and compact when compared with mechanical isolation valves, therefore an ideal choice for the system.

Current status:

As stated above, the electronic air pressure regulator is at a development stage where it is ready to undergo a Critical Design Review (CDR). Upon prosperous completion of the CDR, the electronic Pressure regulator is ready to undergo full qualification. Full qualification would involve qualification level environmental testing (vibration, shock, thermal cycling, etc.) and qualification level testing including on/off cycles and Tvac testing.